Sustainability through innovation

What do we want to leave behind for future generations? That question is our driving force. A responsibility in every part from the earliest stage of the innovation process to finished installation.

Reduce emission

Think about it. Removing or renovating pipes through excavation require a lot of man hours, machines, transportation and sometimes under dangerous conditions. Curing liners with UV is faster, safer and can reduce emissions up to 80 percent, lowering the cost at the same time. Inpipe are continuously setting goals to reduce emissions and environmental impact throughout the supply chain, from raw materials to the installed product.

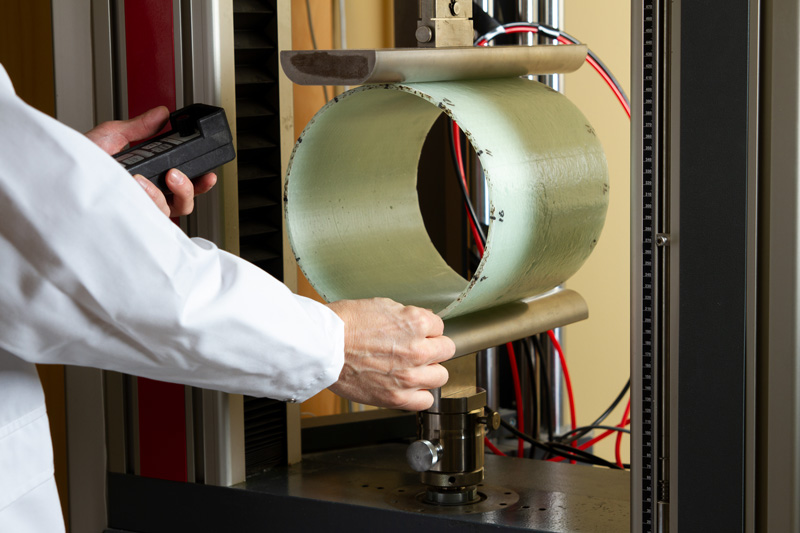

Better products

Inpipe’s products consist of fiberglass, polyester and foils. We are always trying to reduce chemicals during production or replace them with better alternatives.

Fiberglass: manufactured from a type of glass where the use of so-called fluxes has been reduced, in order to also reduce environmentally hazardous emissions.

Polyester: The Inpipe Freeliner® is the world’s first fiberglass-reinforced polyester liner that is completely free of styrene and bisphenol.

Foil: the plastic foils used are made from recyclable plastics.

Valuable insights for a more sustainable future

At Inpipe we prioritize sustainability and environmental responsibility. As part of our commitment to transparency, we have conducted Environmental Product Declarations (EPDs) and Life Cycle Assessments (LCAs) for our products.

These assessments provide valuable insights into the environmental impact of our products from raw material extraction to production and use. By analyzing various stages of the product life cycle, we ensure that our customers have a comprehensive understanding of the environmental footprint associated with our products.

Through EPDs and LCAs, we demonstrate our dedication to minimizing environmental impact and promoting sustainable practices. Explore our product range with confidence, knowing that we are actively working to reduce our environmental footprint and contribute to a more sustainable future.

ISO certified

We are certified according to ISO 9001. The management system describes how we improve and adjust our operations to meet customer needs. We guarantee 100 percent traceability of materials and can track all stages of the finished product. We also have systems to handle customer feedback.

BASTA-registered

Inpipe Freeliner® is BASTA-registered, meaning that the product meets the set criteria regarding environmental and health hazardous properties